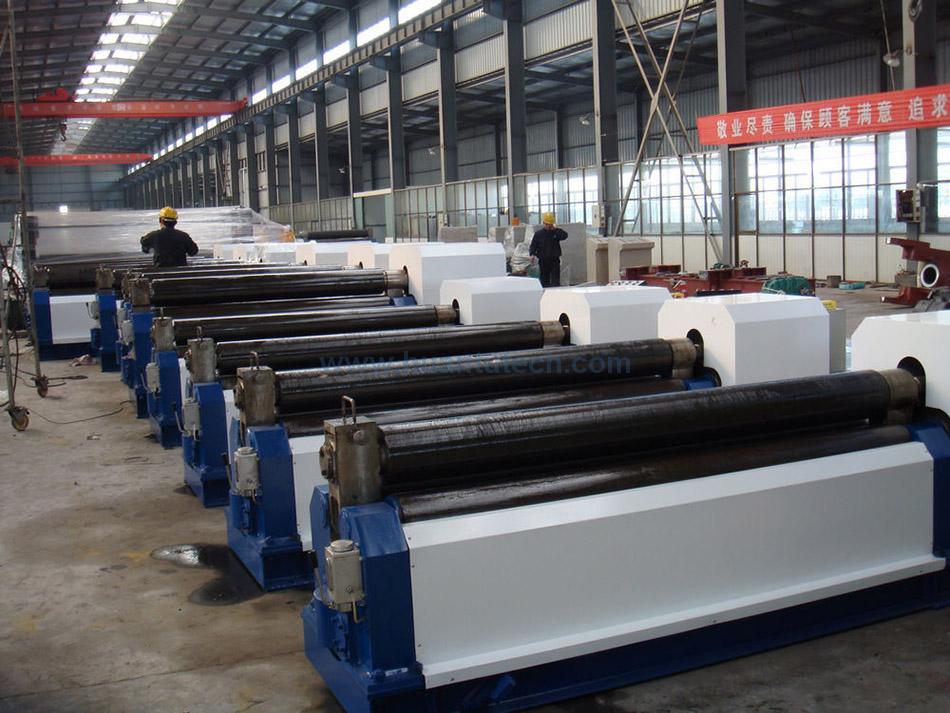

I.Machine usage range

This device is three rollers symmetrical mechanical rolling machine. It is used to

Bend steel into drums shape with different diameters. And it is widely used in boiler industry,chemical industry,mine industry,building industry,shipbuilding industry。

II.Main technical parameters

1 MAIN TECHNIQUE PARAMETER

1. Maximum thickness.........................12mm (iron)/18mm (aluminum)

2. Maximum width.............................3000mm(standard type)

3. Yield limit...............................245MPa

4. Minimum diameter full capacity............700mm

5. Top roller diameter.......................280mm

6. Bottom roller diameter....................240mm

7. Central distance...................... .........360mm

7. Motor.....................................11KW

8. Speed of rolling....................................4m/min

9. Dimension(L×W×H)......................... 5100mm*1300mm*1300mm

10.Weight............................................ 6200KG

Remarks: All the 3 rollers spoiled after heat treatment.

III.Main structure and work principle

A.This machine is symmetrical rolling machine,down up roller and then let up and down

rollers do opposite roll to bend steel plate.

B.This machine composed of two parts those are working part welded in whole chassis and moving part. Working part composed of left and right bearing base,one up roller,two bottom rollers (the material of the three rollers is 45#steel and do heat treatment),lifting screw and turbine and other accessory parts. Down rollers drive up roller to move,up roller can do up and down move by height way. Drive part composed of main motor,main speed reducer and other accessory parts.

C.Bottom rollers were drove by main motor through main speed reducer,output spindle of main speed reducer driven to two down rollers by one group gears,the revolve direction of rollers adjusted by main motor.

D.Upper roll lifted by accessory motor through vice speed reducer drive worm and worm wheel mechanism of right/left rolls bearing base. That to let the lifting pole do up and down move.

E.Unloading device is designed to remove the workpiece after drums bended into shape. Before unloading the upper rolls move to up limit position,the balance device on upper rolls ends hit upper rolls ,draw out the spindle of the pin ,then to remove the workpiece.

IV.Material and quality of roll shaft and process art

A.The material of rollers: 45# steel.

B.Manufacturer : China

C.Files: provide material certificate of forging,and other inspection reports

D.Process art: caststeel ingot—forge semifinished product?—fire treatment after forge—rough treatment by lathe—heat treatment—accurate treatment by lathe—quench in surface.

E.Requirements of heat treatment: quench in surface: osmosis depth of quench≥ 3mm (single side),strength≥HRC45-50.

V.Welding joint components

Includes:rack of machine,base,and other steel components.

Art-flow of welding components

Inspect plate—pre-handle plate—provide material—process the mouth of slope—welding—inspect weld bead—anneal treatment—rough prose??—vibrate limitation—accurate treatment—rust cleaning in surface,corrosion prevent—paint.

VI.Supply range and packing

A.Body part

Up and bottom rollers devices,main motor device,balance device,rack of machine,base and so on.

B.Electrical control system

C.Lubrication system

D.Components related to the whole machine

E.Spare part provide by machine

F.Technical files provide by machine

a.Install drawing,electronic drawing,reference ,certificate,container loading list.

b.Inspection of material,report of heat treatment,material machine test and so on.

VII.Manufacturers of main components

A.Main motor:SIMENS

B.Speed reducer:China

C.Compound bearing:China

D.Main electrical component SIMENS

E.Spindles of rollers:China

VIII.Inspection

A.Accepting this machine by 《technology file》,standards currently in effect of rolling machine,standards provide by seller.

B.Two stages of acceptance

a.Pre-acceptance by seller,send out goods after it qualified.

b.Acceptance by buyer,includes check container loading list,check the device,install,test and do rolling test.

IX.This technical file as the annex of the contract,has law force at same time. Excepts the changes agree with two sides.